- +86 18037866379

- +86 18037866379

- mic@zkcorp.com

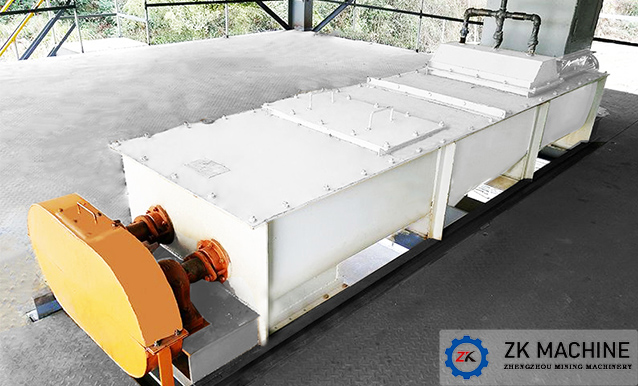

Stirring Blade Diameter: 300 - 900 (mm)

Stirring Shaft Speed: 50 - 32 (r/min)

Capacity: 3 - 90 (t/h)

Application: Clay, sludge, fly ash, coal gangue, etc.

| Model |

Stirring blade diameter (mm) |

Stirring shaft speed (r/min) |

Capacity (t/h) |

Using spiral angel |

Motor power (kW) |

Stirring moisture (%) |

| ZJ300 | 300 | 50 | 3~5 | 12~21 | 11~18.5 | 3~25 |

| ZJ400 | 400 | 48 | 5~12 | 12~21 | 15~30 | 3~25 |

| ZJ500 | 550 | 45 | 12~20 | 12~21 | 22~45 | 3~25 |

| ZJ600 | 600 | 43 | 15~25 | 12~21 | 30~55 | 3~25 |

| ZJ650 | 650 | 41 | 20~40 | 12~21 | 30~55 | 3~25 |

| ZJ700 | 700 | 40 | 30~50 | 12~21 | 37~75 | 3~25 |

| ZJ800 | 800 | 36 | 40~70 | 12~21 | 45~90 | 3~25 |

| ZJ900 | 900 | 32 | 60~90 | 12~21 | 55~132 | 3~25 |