- +86 15237956296

- +86 15237956296

- mic@zkcorp.com

Diameter: 1000 - 4200 (mm)

Height: 250 - 800 (mm)

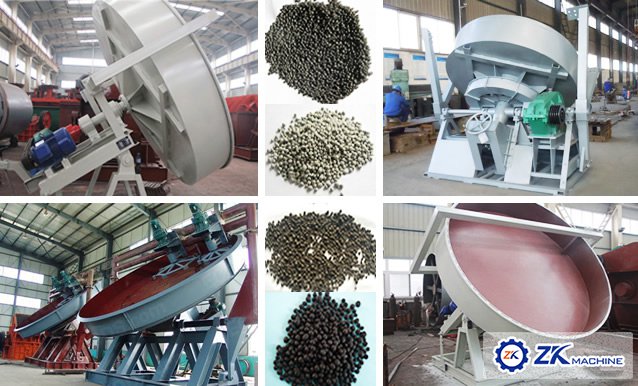

Application: Clay, Coal, Fly ash, LECA Balls, etc.

Type: unpowered / powered scraper

| Model | Dia(mm) | Height(mm) | Slope(°) | Speed(r/min) | Main Drive Motor Power (kW) | Scraper Motor Power (kW) | Weight(t) |

|---|---|---|---|---|---|---|---|

| PQ10 | 1000 | 250 | 35-55 | 2.5-25 | 3 | 1.1×1 | 0.6 |

| PQ12 | 1200 | 250 | 35-55 | 2.5-25 | 4 | 1.1×1 | 0.8 |

| PQ16 | 1600 | 300 | 35-55 | 2-19 | 7.5 | 1.5×1 | 1.4 |

| PQ20 | 2000 | 320 | 35-55 | 1.5-15 | 7.5 | 2.2×1 | 2.2 |

| PQ22 | 2200 | 350 | 35-55 | 1.4-14 | 15 | 2.2×1 | 3.8 |

| PQ25 | 2500 | 350 | 45-55 | 1.2-12 | 15 | 2.2×1 | 5 |

| PQ28 | 2800 | 400 | 45-55 | 1.2-12 | 18.5 | 2.2×1 | 5.8 |

| PQ32 | 3200 | 400 | 45-55 | 1.2-12 | 22 | 3×1 | 8.5 |

| PQ36 | 3600 | 550 | 45-55 | 1-10 | 30 | 3×2 | 9.8 |

| PQ42 | 4200 | 550 | 45-55 | 1-10 | 37 | 4×2 | 12.5 |

| PQ45 | 4500 | 550 | 45-55 | 1-9 | 45 | 4×2 | 13.5 |

| PQ50 | 5000 | 650 | 43-53 | 6-9 | 55 | 5.5×2 | 18 |

| PQ55 | 5500 | 650 | 43-53 | 5.7-8.5 | 75 | 5.5×2 | 30.2 |

| PQ60 | 6000 | 650 | 43-53 | 5.7-8.5 | 90 | 5.5×2 | 32.8 |

| PQ70 | 7000 | 650 | 43-53 | 5.1-7.9 | 132 | 5.5×3 | 45.9 |

| PQ75 | 7500 | 650 | 43-53 | 5.1-7.9 | 160 | 5.5×3 | 50 |