Application of Automatic Control Part in Ceramsite Calcinati

Date:2021-03-12 17:08:04

Author:admin

Views:

113

As the demand for the ceramsite production line becomes more environmentally friendly and the main processing purpose changes, when designing the ceramsite production line, the ideas we consider are also constantly changing, gradually extending to the standardization and automation aspects.

Firstly, when designing the ceramsite rotary kiln, the temperature and pressure measurement of the kiln head and kiln tail cover should be considered to detect the working conditions in the kiln during operation, and then to adjust the burner air volume and kiln tail intake. The speed of the fan reaches a state of equilibrium in working conditions. It turns out that some small production lines are not equipped with some measurement and control methods, which can only be judged manually. While there are some errors, it will also increase the difficulty of standardization management and cost reduction for enterprises.

Secondly, in the aspect of burner automation control, add more sensors to collect data, and finally realize the purpose of automatic temperature control.

Adding temperature and pressure sensors at the inlet and outlet of the dust collector can not only protect the bag from being burned, but also help the operator to judge whether the dust collector is faulty and help normal operation.

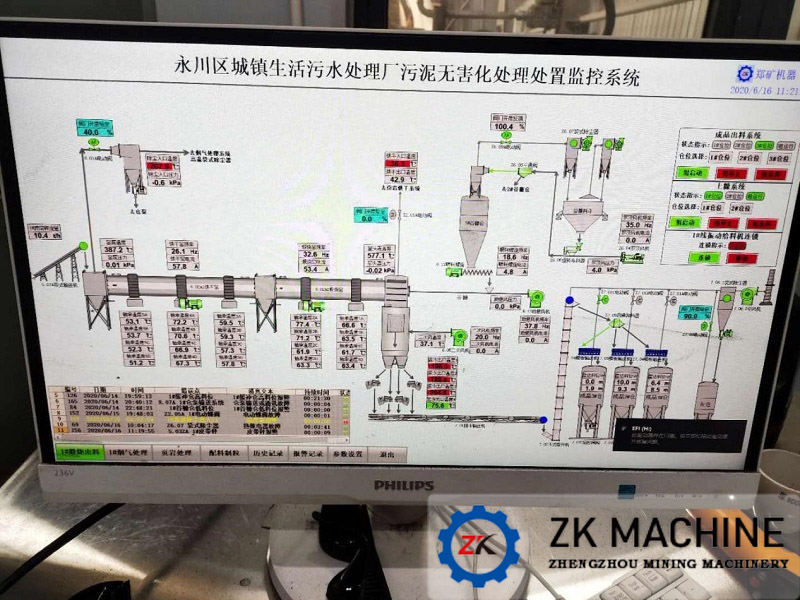

In the entire production line, a central control system is set up to realize not only local control but also remote control. Finally, it is equipped with a station monitoring system to realize the unified movement of workers, raw materials and stations in the whole factory, and realize management without waste and the efficiency of production is improved.

With the improvement of automation level, in the subsequent design of ceramsite, we will also take into account the characteristics of ceramsite production itself to make some changes to make the production line more suitable for our production conditions.