Production Process of Calcium Carbonate Powder Grinding Plan

Date:2021-03-12 16:53:09

Author:admin

Views:

217

Heavy calcium carbonate, referred to as heavy calcium, is made from natural carbonate minerals such as calcite, marble, and limestone. It is a commonly used powdery inorganic filler with high chemical purity, high inertness, difficult chemical reaction, good thermal stability, no decomposition below 400 °C, high whiteness, low oil absorption, low refractive index, soft and dry. It does not contain crystal water, low hardness, low abrasion value, non-toxic, odorless, odorless, and good dispersibility. According to different particle size, it is divided into: ordinary heavy calcium powder, ultrafine heavy calcium carbonate, wet grinding ultrafine calcium carbonate, and ultrafine surface modified heavy calcium carbonate.

Calcium Carbonate Grinding Mill is the main equipment during the calcium carbonate powder grinding plant, which is suitable for grinding calcium carbonate into fine powder. Calcium Carbonate Powder Making Machine is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so on.The purpose of the micro powder grinding millis for super-fine grinding materials with hardness less than 9 in Moh's scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds.

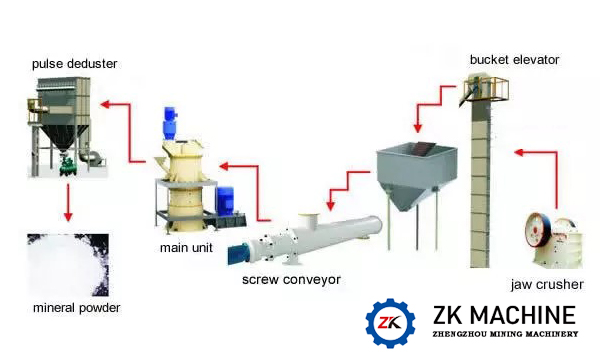

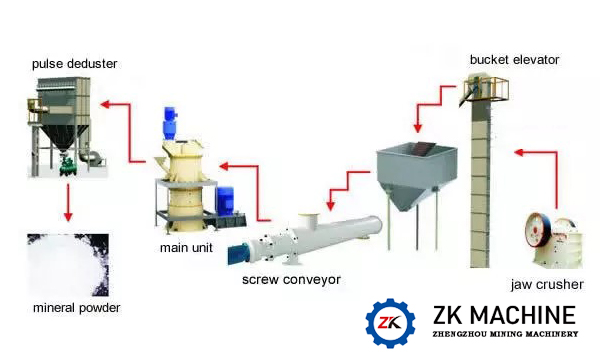

Production Process of Calcium Carbonate Powder Grinding Plant:

First. Crushing

Natural carbonate minerals such as calcite, marble, limestone and other bulk materials are crushed by a crusher to a fineness (15mm-50mm) that can enter the mill.

Second. Grinding

The crushed small pieces of material are sent to the silo through the hoist, and then uniformly and quantitatively fed into the mill grinding chamber through the vibrating feeder for grinding.

Third. Grading

The ground material is graded by a classifier, and the unqualified powder is classified by the classifier and returned to the main machine for re-grinding.

Fourth: Powder Collection

The fine powder conforms to the airflow and enters the dust collector through the pipeline for separation and collection. The collected finished powder is sent to the finished silo by the conveying device through the discharge port, and then uniformly packaged by the powder tanker or the automatic baler.