How to Choose the Appropriate Granulation Equipment?

Date:2020-04-09 14:42:34

Author:admin

Views:

107

Can we form the powder or granular material into a specific shape? Where can I do a ball-making experiment? These problems have plagued many people. At present, ZK Corp has developed and produced a variety of granulation and pelletizing equipment, which can meet the customer's pelleting experiment requirements.

Customers can determine the appropriate pelletizing and pelleting methods through experiments. The ZK Corp test line has different types of granulation equipment such as disc pelletizer, pan granulator, clean-powerful granulator, double roller granulator and drum granulator and so on. If you are not clear which pelleting method to choose, you can mail the materials to Henan Zhengzhou Mining Machinery Co.,Ltd., our company can provide testing services for different formulations of materials, through the pelletizing test to determine the appropriate proportion of pelletizing materials, and recommend reasonable pelleting equipment for you.

1. Disc Pelletizer. The disc pelletizer is suitable for the production of 1mm ~ 20mm spherical products, which can be continuously discharged and the output is high. On the premise of meeting the technological requirements, the disc pelletizer is a relatively cost-effective pelletizer.

Disc Pelletizer

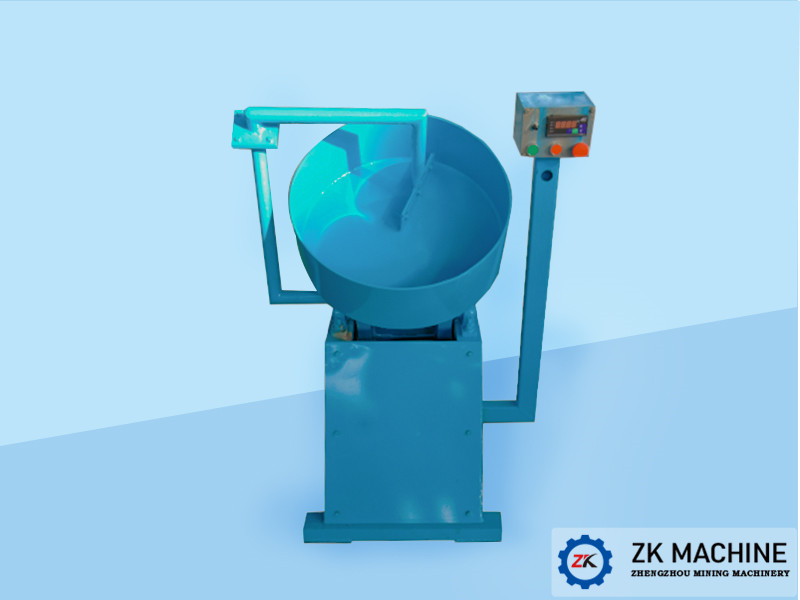

2. Pan Granulator. The pan granulator is suitable for the production of 0.09mm ~ 5mm spherical products. The pan granulator is for intermittent discharge. After a pot of material is prepared, the material is discharged from the discharge port. The pan granulator has a higher strength than the disc pelletizer and has less dust spreading to the environment.

Pan Granulator

3. Clean-Powerful Granulator. The clean-powerful granulator is suitable for producing finished granules from 0.09mm to 4mm. The clean-powerful granulator is designed for intermittent discharge. After a pot of material is prepared, the material is discharged from the discharge port. Because the clean and powerful granulator is completely sealed, it hardly diffuses dust into the environment.

Clean-Powerful Granulator

4. Drum Granulator. The drum granulator has a simple structure, reliable equipment, stable operation, small maintenance workload, strong adaptability of raw materials, and large output of a single machine. However, the use area of the drum is small, the equipment is heavy, the power consumption is high, the size of the raw ball is uneven, and the strength is poor.

Drum Granulator

5. Double Roller Granulator. The double roller granulator is mainly used for building ceramic granules, which are granulated by extrusion between two rollers. The finished product is generally 8-14mm cylindrical. The structure is simple, the operation and maintenance are convenient, but the roller skin is a wearing part, and the general replacement cycle is 6 months.

Double Roller Granulator

If you want to check the strength of the dry ball, ZK Corp can also dry the raw ball and send the finished product to you. If you want to know more equipment parameters and quotations, please consult the customer service of ZK Corp online or call us, we will serve you wholeheartedly!