- +86 18037866379

- +86 18037866379

- mic@zkcorp.com

Model: Φ1200x2400 -- Φ2900x4700 (mm)

Capacity: 1.2 - 16 (t/h)

Increase Production: 10%-20%

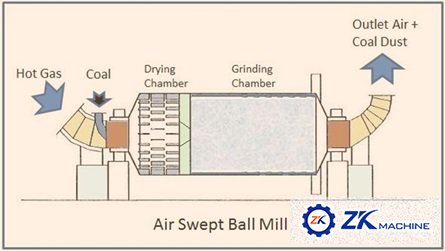

Application: Coal Power Plant, Cement Plant, etc.

| Model |

Grinding body load (t) |

Rev. speed (r/min) |

Capacity (t/h) |

|

Overall dimensions L×W×H (mm) |

Weight (t) |

||

| Model | Power (kW) | Voltage (V) | ||||||

| Φ1200×2400 | 4.8 | 32 | 1.2-4 | Y280M-8 | 45 | 380 | 6520×2850×2540 | 11.2 |

| Φ1500×3000 | 8 | 28.8 | 2-3 | JR125-8 | 95 | 380 | 7604×2630×2698 | 19.7 |

| Φ1700×2500 | 7.5 | 24.5 | 3-5 | JR116-6 | 95 | 380 | 6998×3700×2628 | 24 |

| Φ2200×3000 | 13 | 22 | 5-6 | JR136-8 | 180 | 380 | 7680×4389×2628 | 33.5 |

| Φ2200×4400 | 21 | 8-9 | YRKK4501-6 | 250 | 380 | 7880×4420×3950 | 39 | |

| Φ2200×5800 | 21 | 5.5-7 | Y4005-8 | 280 | 380 | 9060×4480×3950 | 45.8 | |

| Φ2400×4750 | 22 | 20 | 10-12 | YR400-8 | 280 | 6000 | 7770×5266×4024 | 49 |

| Φ2400×(4000+2000) | 10-11 | YRKK450-8 | 250 | 6000 | 10600×5500×4024 | 56 | ||

| Φ2400×(4500+2000) | 10-12 | YRKK500-8 | 280 | 6000 | 11200×5500×4024 | 59.6 | ||

| Φ2500×3900 | 14 | JR138-8 | 280 | 6000 | 8770x6266x4870 | 53 | ||

| Φ2600×(5250+2250) | 9-10 | YRKK500-8 | 400 | 6000 | 74.3 | |||

| Φ2800×(5000+3000) | 13-13.5 | Y5001-8 | 500 | 6000 | 86.2 | |||

| Φ2900×4700 | 35 | 18.6 | 16 | JSQ1512-6 | 570 | 6000 | 8930x6179x4440 | 81 |