Types of granulators and their scope of application

Date:2022-06-24 11:05:25

Author:admin

Views:

120

Granulators are widely used in chemical, building materials, metallurgy, pharmaceutical, fertilizer, plastic, food and other industries. The granulators produced by our company are generally used in building materials and metallurgical industries, mainly in the following categories:

1. Disc granulator

The disc pelletizing machine is mainly used in chemical fertilizer, building materials, metallurgy and other industries. The particle size is generally Φ3-Φ10mm, and it can continuously feed and discharge. At present, the diameter of the largest disc balling machine manufactured by our company is 5m, and the output can reach 40-45t/h. This kind of granulator is divided into two types: powered scraper and non-powered scraper. Generally, when customers are recommended, the non-powered scraper is used to form a ball plate when the size is less than Φ2.0m, unless the customer has special requirements.

2. Pot granulator

The pot granulator is mainly used in the petroleum proppant industry, and the particle size is generally 30-140 mesh. At present, the maximum diameter of this granulator produced by our company is Φ4.2m, and the volume reaches 14m³. This kind of granulator generally has stricter requirements for powder materials, and the fineness of powder materials is generally above 325 mesh, the higher the yield.

3. Double roller granulator

The counter-roll granulator is mainly used for building ceramsite, which belongs to extrusion granulation, and the finished product is generally 8-14mm cylindrical. At present, the largest granulator produced by the company is Φ800×700, with an output of 6-8t/h, simple structure, convenient operation and maintenance, but the roller skin is a wearing part, and the general replacement cycle is 6 months.

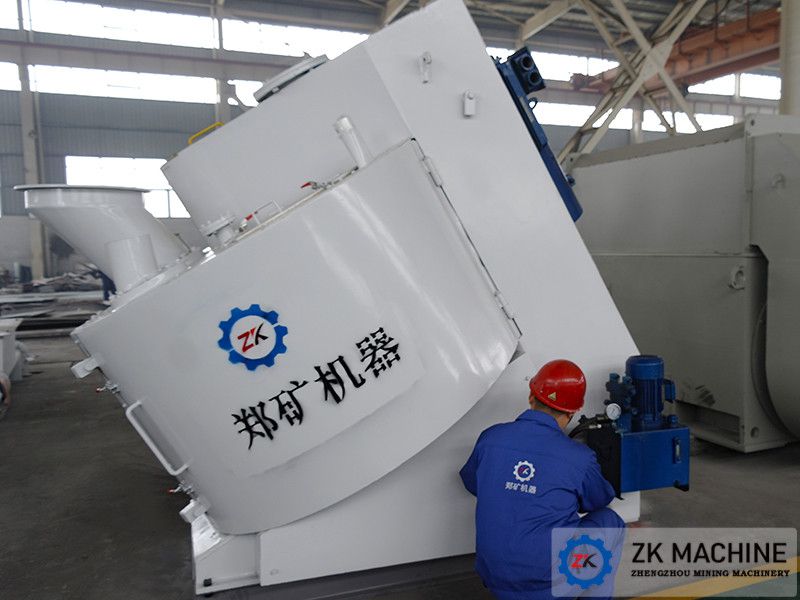

4. High-efficiency granulator

The ZKZL series clean powerful granulator produced by Henan Zhengkuang Machinery Co., Ltd. is developed on the basis of absorbing and learning from foreign mature technology, combined with the current production status of oil fracturing proppant in my country, and is mainly used in oil fracturing proppant It can also be used in the production of powdered, granular and small pieces of coal powder, limestone, coal gangue and clay into balls.

It is mainly used in the formation of oil proppant primers. At present, the largest diameter produced by the company is Φ1.9m, and the volume reaches 1000 liters.

5. Drum granulator

The drum granulator is consistent with the application industry of the ball-forming disc. At present, the largest drum granulator manufactured by our company is Φ3.2×8m, which has been exported to Brazil. Its structure is similar to that of a single-cylinder cooler and a dryer. Compared with the ball-forming disc, its ball-forming smoothness and strength are slightly worse.

6. Ball pressing machine

The briquetting machine is mainly used in the metal magnesium industry. It belongs to dry powder briquetting, and the moisture is generally ≤1%. This equipment is generally outsourced by our company, and the production capacity is generally 3-10t/h.

The selection of the granulator generally needs to consider the characteristics of the raw materials, the requirements of the finished product and the related process configuration. If you have any questions about the selection and quotation of the granulator, please feel free to contact us.