Domestic Garbage Incineration Feeding Mechanism

Date:2020-06-23 16:59:22

Author:admin

Views:

185

With the acceleration of the urbanization process, the urban population continues to increase, and the domestic waste generated by people also increases. The amount of domestic waste generated increases at a rate of 10%-15% per year. The traditional waste disposal method-landfill, has been unable to meet the amount of domestic waste generated, the vast majority of the landfills built in the mid-to-late 1990s in China have reached the end of their useful life. In addition, a large number of landfills have caused secondary pollution to the surrounding air, soil, water bodies, etc., and also have a negative impact on the living environment of residents. At the same time, they have occupied a lot of valuable land resources. Therefore, the method of landfill disposal has been unable to meet the requirements of my country's urbanization process.

The comprehensive utilization of household waste incineration power generation and other related technologies is a waste treatment method that is currently used more, and truly realizes the "LJ" five-chemical treatment, that is, "rapid, harmless, no surplus, resources "Recycling and industrialization", waste incineration can use the heat generated by combustion to generate electricity, and the solid residue after incineration can be used as a raw material for light aggregate ceramsite to produce light aggregate ceramsite, thus achieving the "LJ" Five of the Treatment.

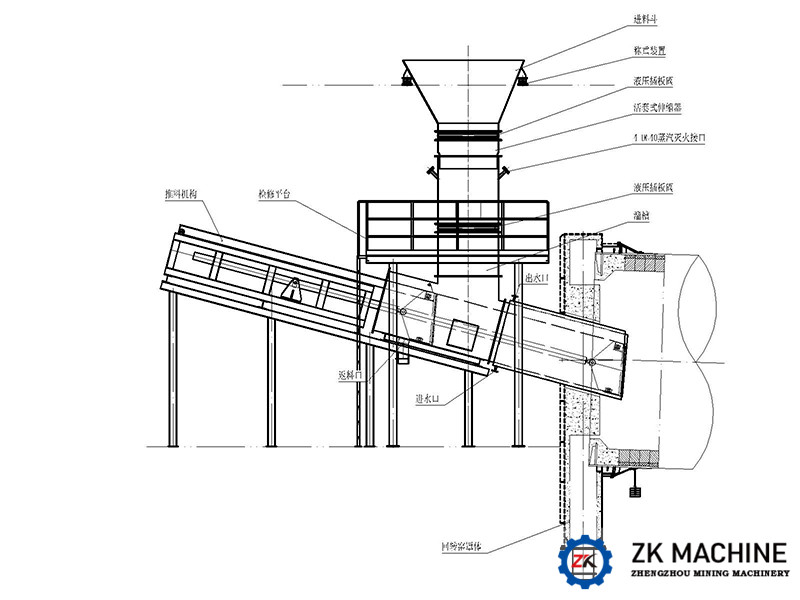

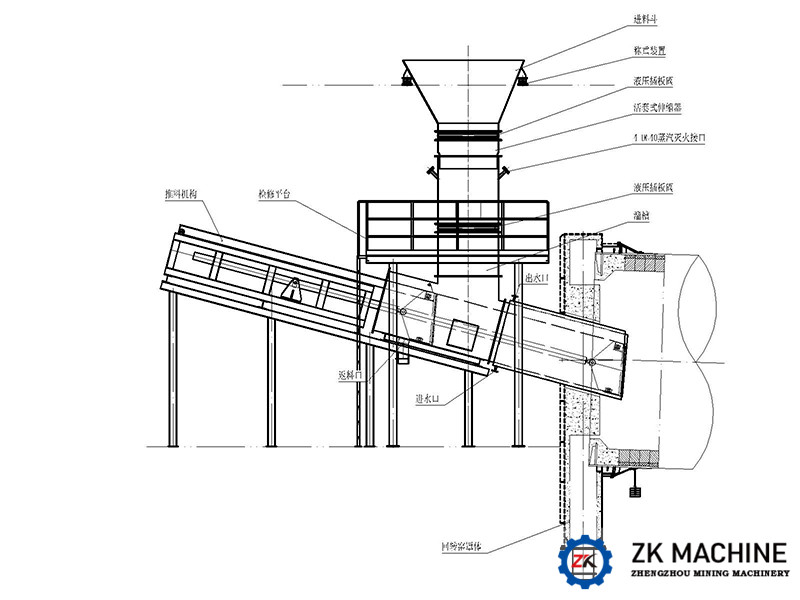

Due to the variety of components contained in the garbage, the garbage enters the furnace and burns, and a special feeding mechanism is needed. The feeding mechanism is mainly composed of a weighing silo, a hydraulic plug valve, a buffer silo, a pushing mechanism, a water-cooled jacket, etc. Composition, a hydraulic plug-in valve is designed at the discharge port of the weighing bin. A cavity is formed between the two hydraulic plug-in valves. The two plug-in valves cannot be opened at the same time. When the upper plug-in valve is opened, garbage materials fall down When the weight loss of the weighing bin sensor reaches the set requirement, the upper hydraulic interposer valve is closed, the lower hydraulic interposer valve is opened, the garbage material falls to the front section of the pusher of the pushing mechanism, and the hydraulic cylinder pushes the pusher to push the garbage Burn it in the kiln. The water-cooled jacket part needs to be inserted into the combustion furnace, the material is made of heat-resistant steel, and the inside is cooled by circulating water.

The structure and principle of the garbage feeding mechanism are very simple, and maintenance is also very convenient, which solves the problem of difficult feeding of garbage.